41 aluminum silicon phase diagram

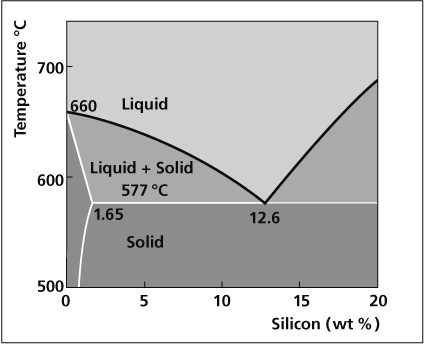

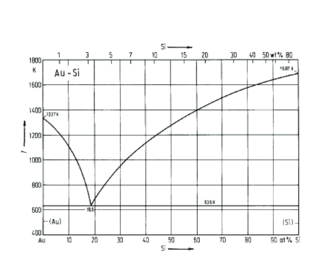

The Al-Si Phase Diagram The binary Al-Si phase diagram was initially studied by Fraenkel of Germany in 1908. It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al and for Al in Si. Thus, the terminal solid solutions are nearly pure Al and Si under equilibrium conditions. Aluminum •"Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust.

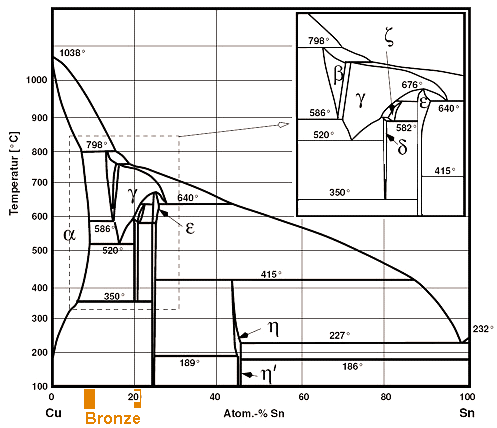

Up to 70 wt% of zinc can dissolve in aluminium, followed by magnesium (17.4 wt%), copper (5.7 wt%) and silicon (1.65 wt%). We shall see that the addition of these elements can radically alter the properties of pure aluminium. Typical Phase Diagrams Typical eutectic and a peritectic phase diagrams are illustrated in Fig. 2; these two forms

Aluminum silicon phase diagram

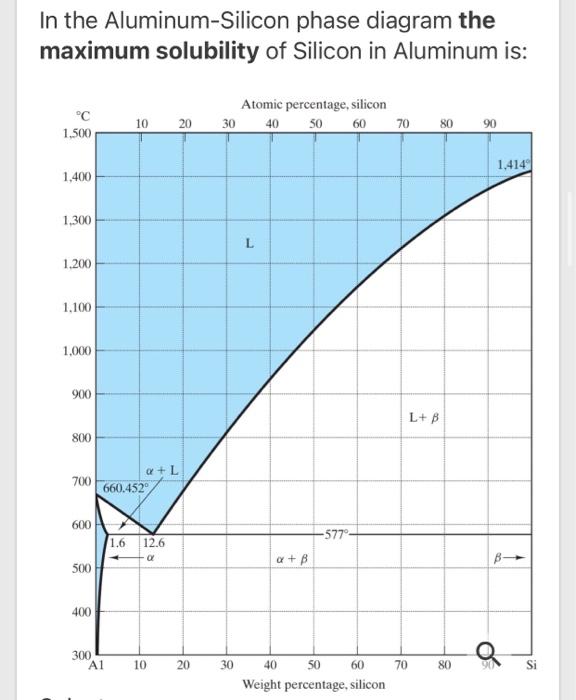

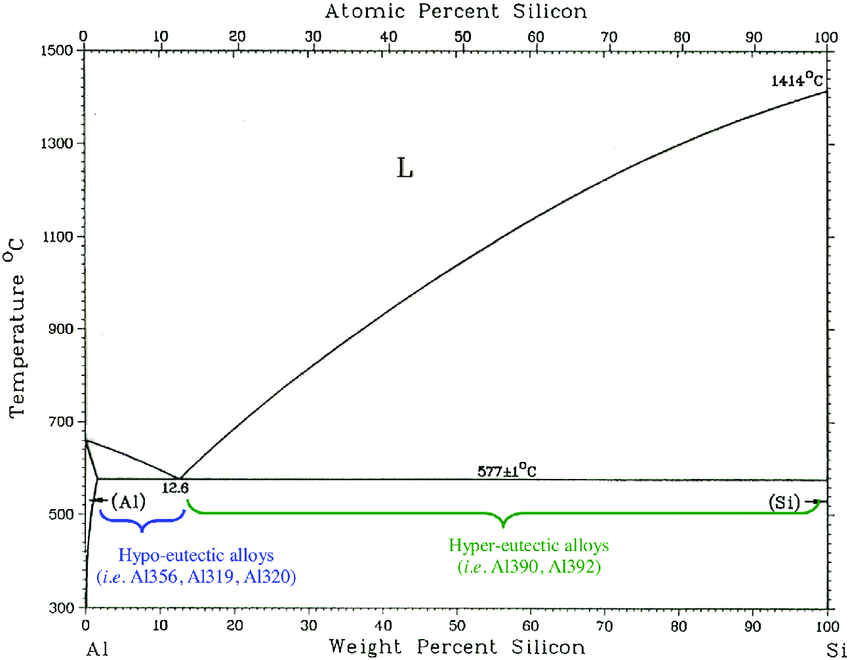

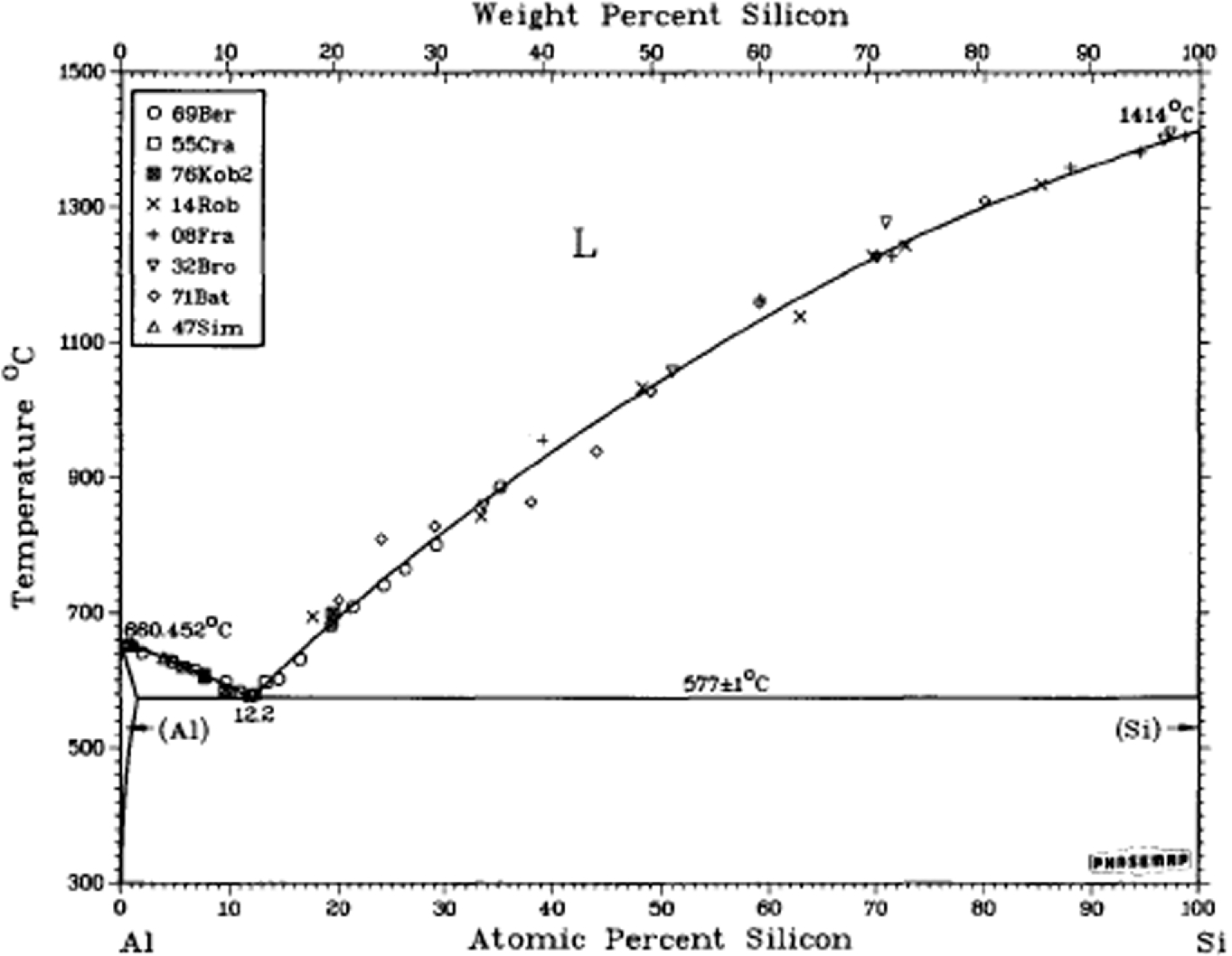

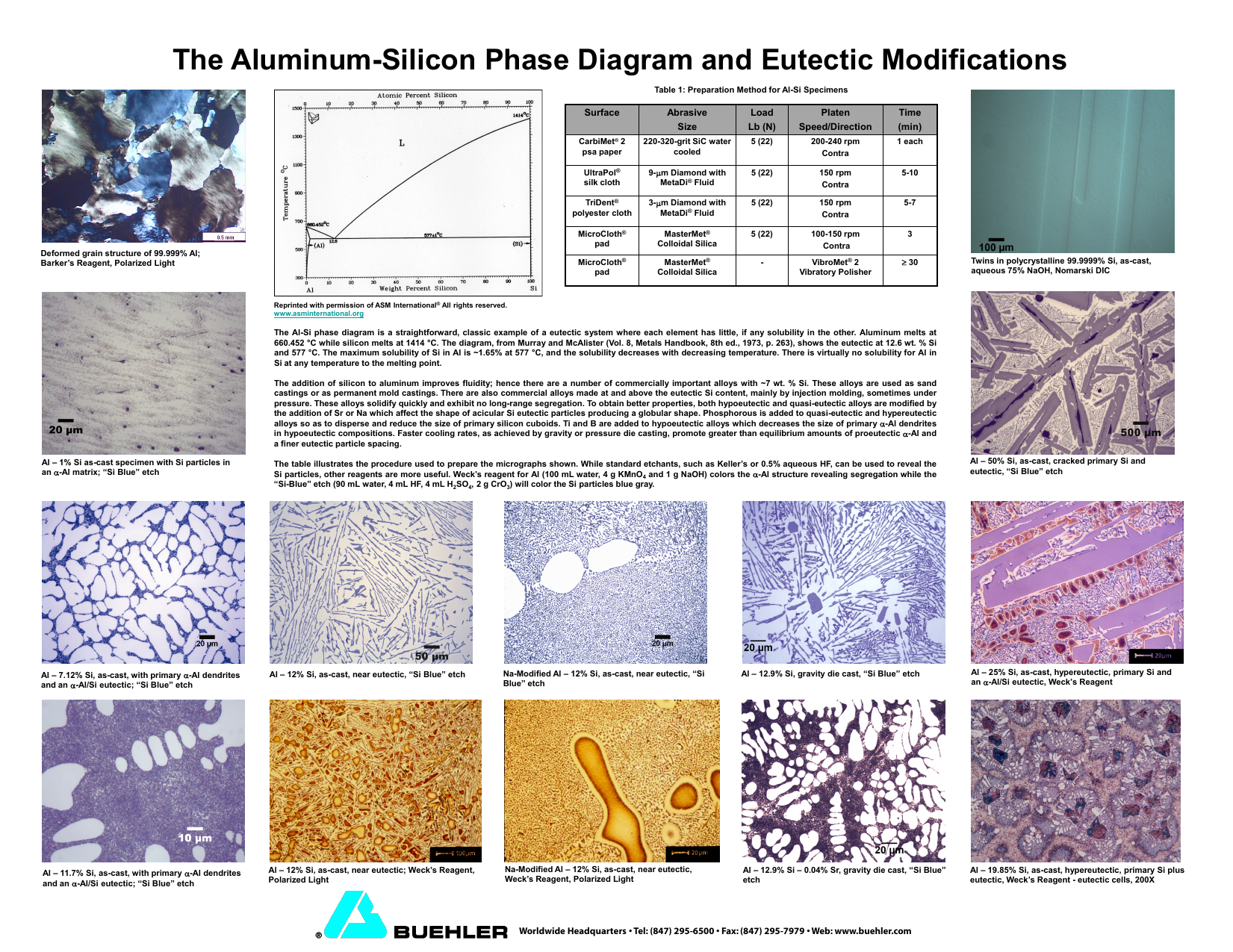

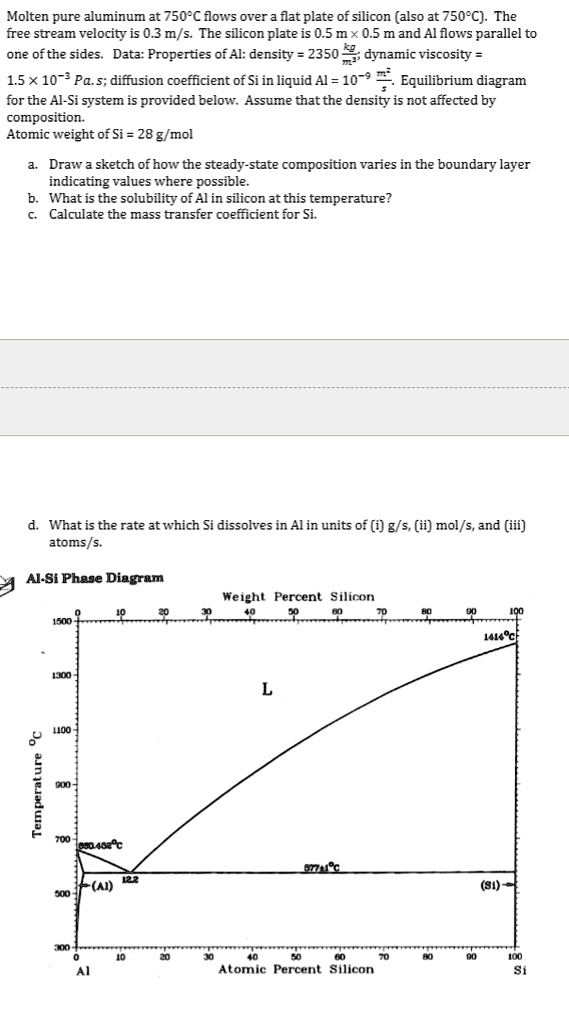

The Al-Si phase diagram is the base component system for the Al-Si series of alloys. As Figure 1 shows, it is a binary eutectic type phase diagram with limited aluminum and silicon solubility. The melting temperature of pure aluminum is 660°C. The solubility of silicon in the aluminum melt reaches a maximum of 1.6 wt.% at the 577°C eutectic ... This phase diagram is for high-purity Al–Si alloys. The two solid phases are labeled (Al) and (Si). You must be aware that Al stands for aluminum as a component (and as an element), whereas (Al) stands for the phase which may be a solid solution. The relationship between composition and the hot cracking of restrained castings in binary aluminium – silicon alloys is shown in Fig. 10.4 and the corresponding section of the aluminium–silicon phase diagram in Fig. 10.5. The degree of cracking rises to a maximum at about 0.5 % silicon and then decreases rapidly as the alloy content is increased.

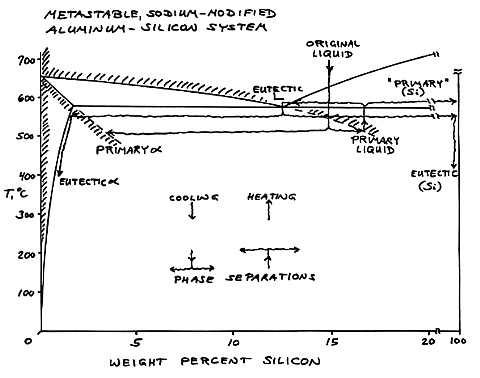

Aluminum silicon phase diagram. The Al-Si phase diagram, a diagram of considerable commercial significance, is the starting point for developing more complex alloys and for understanding their behavior. Si is a common impurity in aluminum alloys, but it is also a deliberate alloying addition in both cast and wrought Al alloys. The Al-Si phase diagram is a straightforward, classic example of a eutectic system where each element has little, if any solubility in the other. Aluminum melts at 660.452 °C while silicon melts at 1414 °C. The diagram, from Murray and McAlister (Vol. 8, Metals Handbook, 8th ed., 1973, p. 263), shows the eutectic at 12.6 wt. % Si and 577 °C. Transcribed image text: 1 In the Aluminum-Silicon phase diagram the maximum solubility of Silicon in Aluminum is: Time left 1:25:35 of °C 1.500 Atomic percentage, silicon 30 40 50 60 10 20 70 80 90 stion 1,400 1,414° 1.300 L 1.200 1.100 1.000 900 LB 800 700 0 + L 660.452 600 577 1.6 12.6 B 500 900 L+B 800 700 Q+L 660.452 600 1.6 -577° 12.6 B- 500 400 300 AL 10 20 30 40 50. 60 70 80 90 Si ... The silicon content in standardized commercial cast aluminum-silicon alloys is in the range of 5 to 23 wt%. The structure of the alloys can be hypoeutectic, hypereutectic, or eutectic, as can be seen on the equilibrium phase diagram (Fig. 1.1a). The properties of a specific alloy can be attributed to the individual physical

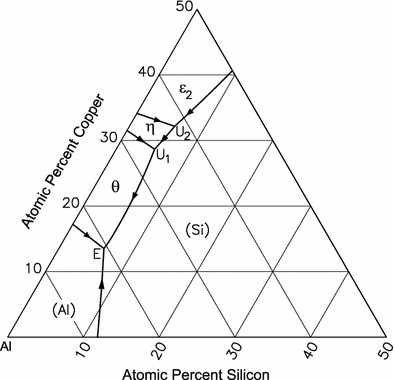

The phase diagram indicates that Silicon is present in two forms: the primary Silicon crystals and the Aluminium-Silicon . Chat Now Send Inquiry; Solidification of Al-Si alloys - Top 1% UK... Al-Si alloys differ from our "standard" phase diagram in that aluminium has zero solid solubility in silicon at any temperature. Chat Now Send Inquiry Al-Si phase diagram [1]. In recent work on the solidification of hyper-eutectic Al-Si alloys789 based upon the concept of the solubility of barium (Ba) metal in the silicon phase it has been... Al-Si alloys differ from our "standard" phase diagram in that aluminium has zero solid solubility in silicon at any temperature. This means that there is no beta phase and so this phase is "replaced" by pure silicon (you can think of it as a beta phase which consists only of silicon).. So, for Al-Si alloys, the eutectic composition is a structure of alpha+Si rather than alpha+beta. Aluminum-Magnesium-Silicon Ternary Alloy Phase Diagram. Ternary isothermal diagram ( 427°C), crystal data, melting points. D.Ludecke, (1986) Phase Diagram and Thermochemistry of the Al-Mg-Si System, Z. Metallkde., 77 278-283.

Phase diagram reproduced with permission from Mikael Schalin, Royal Institute of Science and Technology, Stockholm. Aluminium-silicon alloys form a eutectic at 11.7 wt% silicon, the eutectic temperature being 577 oC. This represents a typical composition for a casting alloy because it has the lowest possible melting temperature. Phase diagram. Aluminum End of Al-Si Phase Diagram. The melting characteristics of the cladding alloys are governed by the Al-Si phase diagram. The eutectic composition, i.e. the amount of Si required to produce the lowest melting point is 12.6%. The melting point at this composition is 577°C. At lower Si levels the solidus or the point at ... Aluminum-Magnesium-Silicon Ternary Alloy Phase Diagram of Phase Diagram Calculations on Teaching, Research and Industrial 12 instances of aluminum alloy phase diagram. If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, we will ... The Aluminum-Silicon Casting Alloys: Atlas of Microstructures provides any engineer or researcher who works with aluminum castings with a practical and substantive tool for the visual analysis of the microscopic images of the microstructure of the aluminum casting alloys, as examined during routine laboratory procedures. The gallery of microstructure images presented in the Atlas has been ...

(full colour version available online) Materials Engineering - Materiálové inžinierstvo 22 (2015) 54-65 60 T. Tański et al.: Thermal, structure and phases analysis of the aluminium ENAC-AlMg5Si2Mn alloy Fig. 3. Al-Mg-Si ternary phase diagram [26]. Fig. 4.

Publisher Summary. This chapter examines the phase composition of alloys that contain magnesium and silicon in the absence of copper. It mentions that the aluminum-magnesium-silicon (Al-Mg-Si) phase diagram can be used for the analysis of many wrought alloys of 6XXX-series and casting alloys of the 356.0 type, provided the concentration of iron impurity is low.

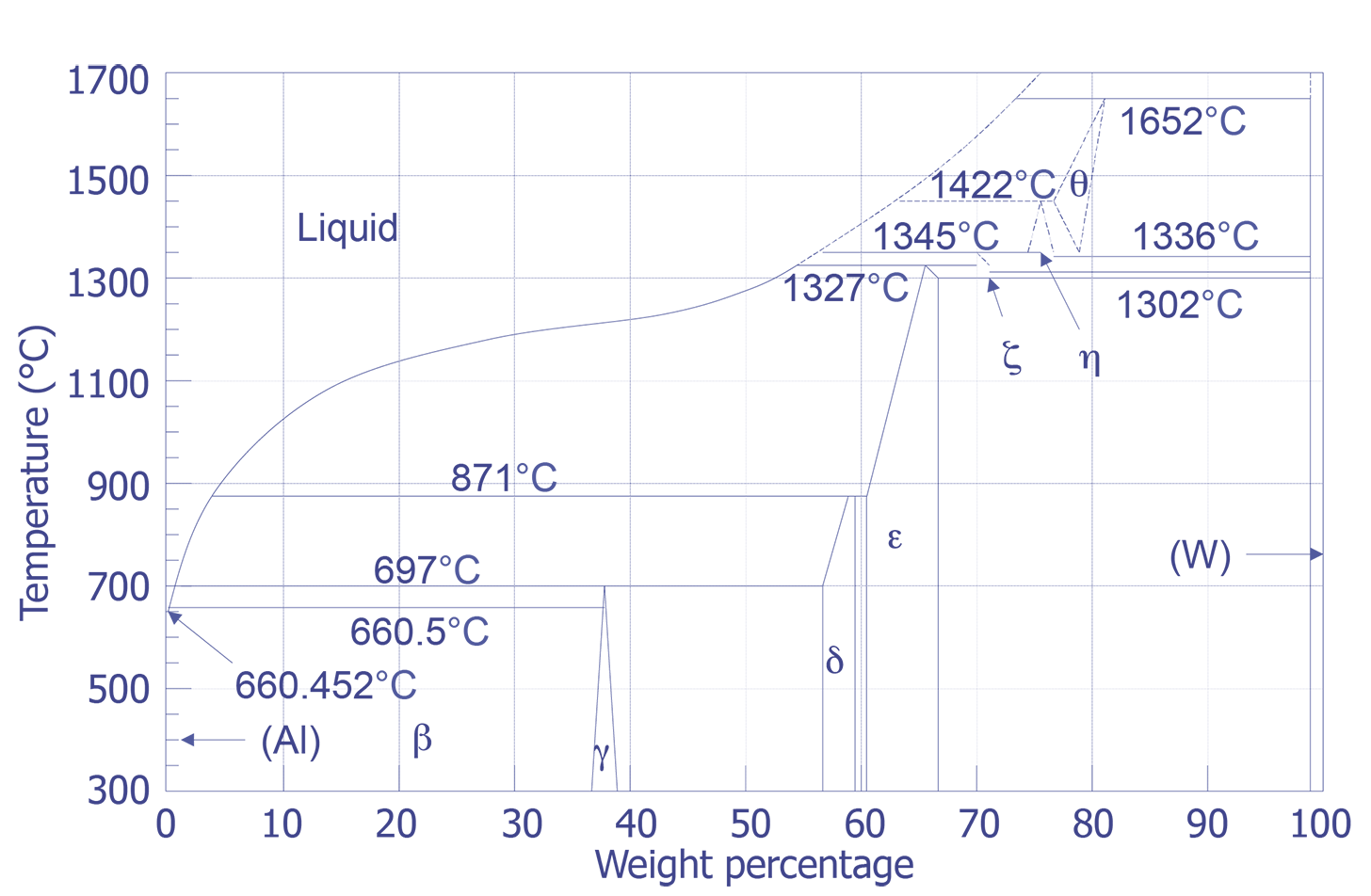

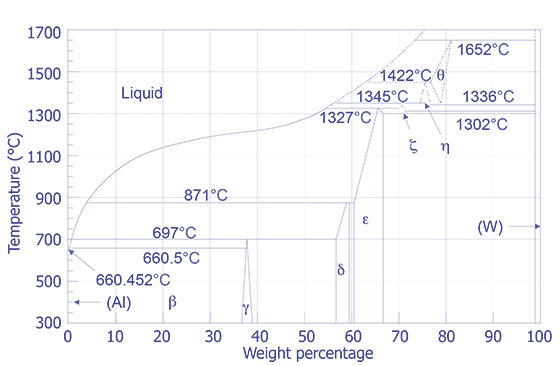

Aluminum - Tungsten Phase Diagram. Coefficients of Thermal Expansion and Resistivity Thermal mismatch between materials is a major source of concern in microelectronics.

by JL Murray · 1984 · Cited by 723 — (Equi Diagram; Experimental). Google Scholar. Indicates key paper 28Dix: E. H. Dix and A. C. Heath, “Equilibrium Relations in Aluminum-Silicon and ...

The Al-Si phase diagram is With starting metals of 99.97% Al, 99.9995% Si, and a simple eutectic type [Massalski2]. The Ni-Si phase dia- 99.97% Ni, [2005Pan] arc melted 53 ternary alloys under Ar gram [1999Du] has a number of intermediate phases: Ni Si atmosphere.

Al-Si is a classical eutectic system, with a phase diagram with characteristics similar in that of the Ag-Cu phase diagram presented above. Alloys of Al and Si are important as casting alloys and we will return to this system in lecture 1205. TALAT 1203 10

Aluminum-Magnesium-Silicon Ternary Alloy Phase Diagram. View/ Open. AlMgSi Phase Diagram from ASM Center (548.5Kb) Date 2013-12-03. Author. ASM International. Metadata Show full item record. Abstract. Ternary isothermal diagram ( 427°C), crystal data, melting points. This item URI

Al-Si diagram is a eutectic diagram where solid solubility at least of aluminium in silicon is negligible, and maximum solubility of silicon in aluminium (at eutectic temperature) is 1.65%. The eutectic composition is 12.7% silicon. Fig. 3.18 illustrates this diagram and photomicrographs of alloys at room temperature.

Download scientific diagram | 4 : Aluminum – silicon phase diagram and microstructures [2]. from publication: Lost foam casting of LM6-Al-Si cast alloy | In the present research, experimental ...

The Al-Si Phase Diagram The binary Al-Si phase diagram was initially studied by Fraenkel of Germany in 1908. It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al and for Al in Si. Thus, the terminal solid solutions are nearly pure Al and Si under equilibrium conditions.

1940Tak: H.P. Takeda and K. Mutuzaki: "The Equilibrium Diagram of the Iron-Aluminum-Silicon System," Tetsu to Hagane, 1940, 26, pp. 335-61 (in Japanese). Google Scholar . 1967Mun: D. Munson: "A Clarification of the Phases Occurring in Aluminum-Rich Aluminum-Iron-Silicon Alloys with Particular Reference to the Ternary Phase α-AlFeSi," J. Inst. Met., 1967, 95, pp. 217-19.

The relationship between composition and the hot cracking of restrained castings in binary aluminium – silicon alloys is shown in Fig. 10.4 and the corresponding section of the aluminium–silicon phase diagram in Fig. 10.5. The degree of cracking rises to a maximum at about 0.5 % silicon and then decreases rapidly as the alloy content is increased.

This phase diagram is for high-purity Al–Si alloys. The two solid phases are labeled (Al) and (Si). You must be aware that Al stands for aluminum as a component (and as an element), whereas (Al) stands for the phase which may be a solid solution.

The Al-Si phase diagram is the base component system for the Al-Si series of alloys. As Figure 1 shows, it is a binary eutectic type phase diagram with limited aluminum and silicon solubility. The melting temperature of pure aluminum is 660°C. The solubility of silicon in the aluminum melt reaches a maximum of 1.6 wt.% at the 577°C eutectic ...

![The Al-Si (Aluminum-Silicon) system - [PDF Document]](https://demo.vdocuments.mx/img/378x509/reader024/reader/2021010212/57506f841a28ab0f07d0b362/r-2.jpg)

![Al-Si cast alloy phase diagram [14] | Download Scientific Diagram](https://www.researchgate.net/profile/Ojo-Sunday-Isaac-Fayomi/publication/286496367/figure/fig1/AS:522638743539712@1501618194999/Al-Si-cast-alloy-phase-diagram-14.png)

0 Response to "41 aluminum silicon phase diagram"

Post a Comment